In today’s industrial sector, energy efficiency is not just a buzzword—it’s a critical component of operational success and sustainability. With rising energy costs and increasing environmental regulations, industries must find ways to optimize energy use while maintaining productivity. Transforming your industrial space to be more energy-efficient can lead to significant cost savings, enhanced operational efficiency, and a reduced environmental footprint. Here’s how you can unlock energy efficiency in your industrial facility.

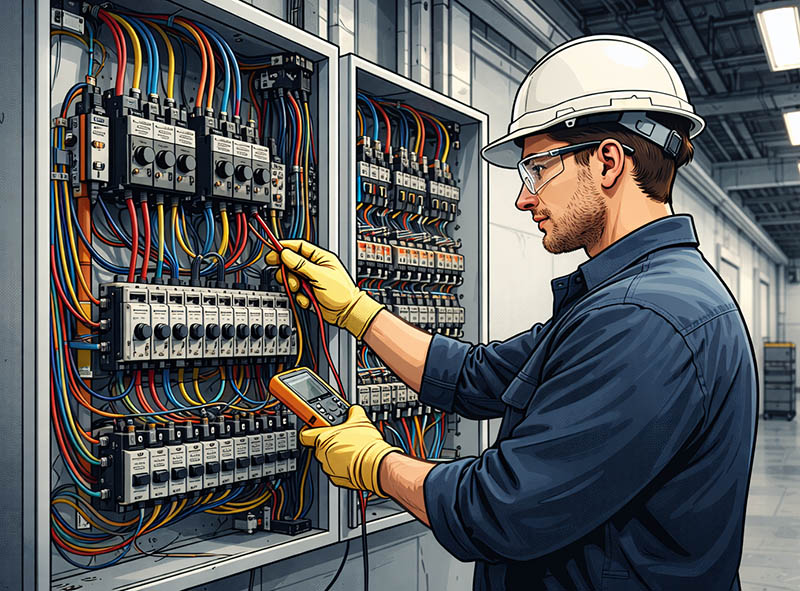

1. Conduct a Comprehensive Energy Audit

The first step towards improving energy efficiency is understanding your current energy consumption. A comprehensive energy audit can help identify areas where energy is being wasted and opportunities for improvement.

Key Components of an Energy Audit:

- Energy Usage Analysis: Examine historical energy consumption data to identify patterns and peak usage times.

- Equipment Assessment: Inspect machinery, HVAC systems, and lighting to determine their energy efficiency and operational status.

- Building Envelope Inspection: Check for insulation issues, air leaks, and other factors that may affect energy consumption.

By addressing the issues identified during the audit, you can prioritize improvements that offer the greatest energy savings.

2. Upgrade to Energy-Efficient Equipment

Older industrial equipment can be a significant drain on energy resources. Upgrading to modern, energy-efficient machinery and systems can drastically reduce energy consumption.

Energy-Efficient Equipment Upgrades:

- High-Efficiency Motors: Replace outdated motors with high-efficiency models that use less energy and provide better performance.

- Variable Frequency Drives (VFDs): Install VFDs to control motor speed and reduce energy consumption during low-demand periods.

- Advanced HVAC Systems: Upgrade to HVAC systems with better energy ratings, programmable thermostats, and zoning capabilities to optimize climate control.

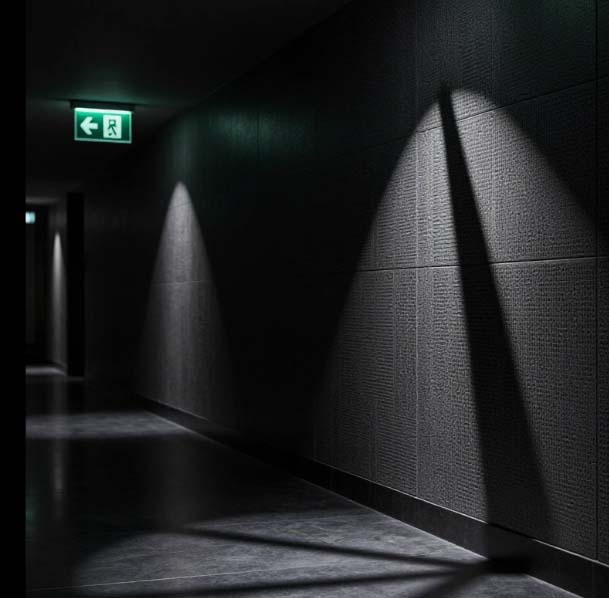

3. Implement Smart Lighting Solutions

Lighting is a major energy consumer in industrial facilities. Switching to energy-efficient lighting solutions can provide substantial savings.

Smart Lighting Strategies:

- LED Lighting: Replace incandescent or fluorescent bulbs with LEDs, which use less energy and have a longer lifespan.

- Occupancy Sensors: Install sensors that automatically turn off lights in unoccupied areas.

- Daylight Harvesting: Utilize natural light by installing skylights and using light sensors to adjust artificial lighting based on daylight availability.

4. Optimize Production Processes

Streamlining production processes can lead to energy savings by reducing waste and improving efficiency.

Process Optimization Techniques:

- Lean Manufacturing: Implement lean principles to minimize waste and improve productivity.

- Energy Management Systems (EMS): Use EMS to monitor and control energy usage in real-time, allowing for adjustments to be made quickly.

- Predictive Maintenance: Adopt predictive maintenance practices to keep equipment running efficiently and prevent energy waste due to malfunctioning machinery.

5. Embrace Renewable Energy Sources

Incorporating renewable energy sources into your energy mix can reduce reliance on traditional energy and lower overall energy costs.

Renewable Energy Options:

- Solar Power: Install solar panels to generate clean energy and reduce grid dependence.

- Wind Power: Consider wind turbines if your facility is in a suitable location.

- Combined Heat and Power (CHP): Utilize CHP systems to produce electricity and useful heat simultaneously, improving overall energy efficiency.

6. Foster a Culture of Energy Efficiency

Encouraging energy-efficient behaviors among employees can amplify the impact of your energy-saving initiatives.

Ways to Promote Energy Efficiency:

- Training Programs: Educate employees on the importance of energy efficiency and best practices.

- Energy Conservation Goals: Set and track energy-saving targets for different departments.

- Incentive Programs: Reward employees for identifying and implementing energy-saving measures.

Trust Eric Gandler Development Electric for Your Energy Efficiency Needs

At Eric Gandler Development Electric, we understand the unique challenges faced by industrial facilities in achieving energy efficiency. Our team of experienced electricians specializes in designing and implementing customized energy solutions that align with your operational goals and sustainability initiatives.

Why Choose Us?

- Expertise in Industrial Solutions: We have extensive experience working with industrial clients to optimize their energy usage.

- Tailored Services: We provide customized energy efficiency solutions that meet the specific needs of your facility.

- Commitment to Sustainability: We are dedicated to helping you achieve your energy efficiency goals while reducing your environmental impact.

Learn More

For more insights on energy efficiency, check out our article on transforming commercial spaces: Unlocking Energy Efficiency: Transforming Your Commercial Space.

Contact Us Today

Ready to transform your industrial space and unlock significant energy savings? Contact Eric Gandler Development Electric today to schedule a consultation and learn how we can help you achieve your energy efficiency goals. Visit our Commercial Services page for more information.