In the intricate web of an industrial setting, where machines hum with purpose and productivity, the role of an electrician is akin to that of a conductor orchestrating a symphony. Among their myriad tasks, one of the most critical is allocating power for equipment. In this blog article, we delve into the intricacies of this process, exploring the considerations, challenges, and expertise required to ensure a seamless and efficient power supply for industrial machinery.

Understanding Industrial Power Needs

The first step in allocating power for equipment is understanding the unique needs of industrial operations. Industrial machinery comes in various shapes, sizes, and power requirements, from small motors to heavy-duty equipment requiring substantial electrical currents. An electrician must assess the types of machinery present, their voltage and amperage requirements, and any special considerations such as three-phase power or motor starters.

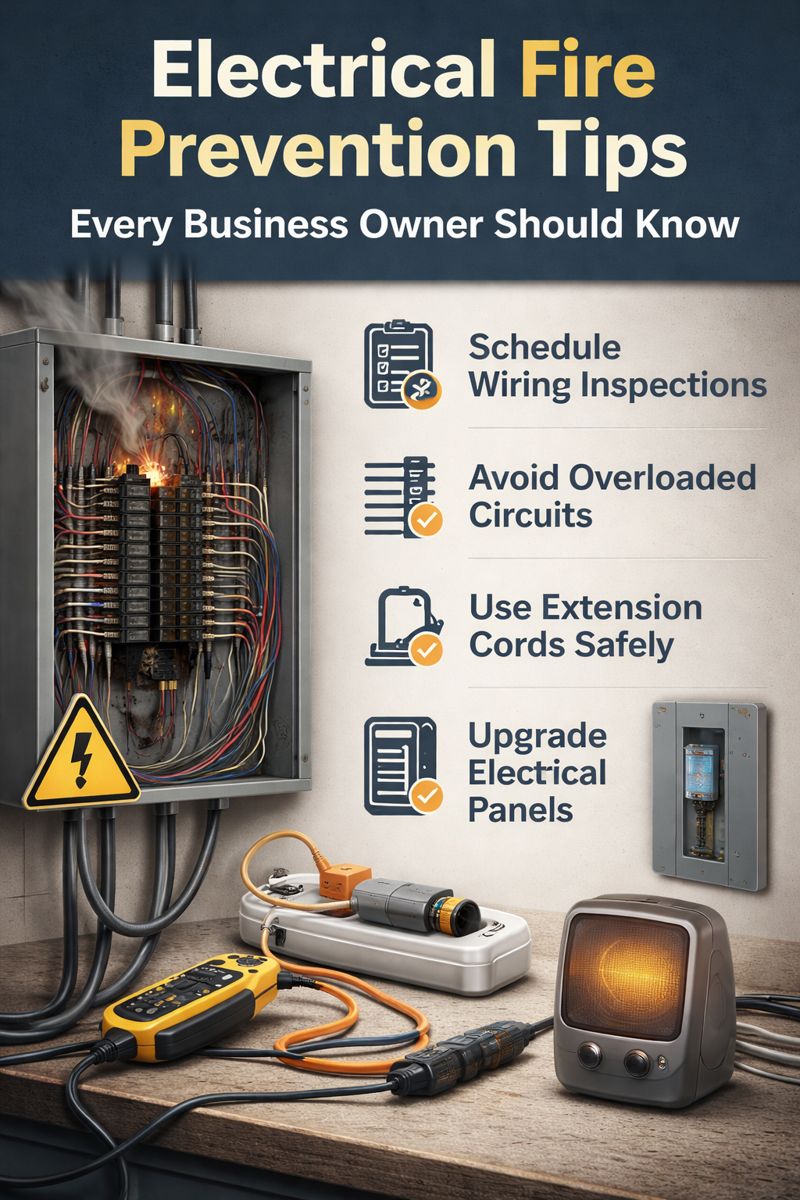

Load Analysis and Calculation

Once the machinery is identified, a load analysis and calculation are performed to determine the total power demand. This involves assessing the power consumption of each piece of equipment, factoring in starting currents (which can be higher than running currents), and considering simultaneous operation scenarios. The goal is to ensure that the electrical system can handle the combined load without overloading circuits or causing voltage drops.

Selecting the Right Distribution Equipment

Based on the load analysis, the electrician selects and installs the appropriate distribution equipment. This includes circuit breakers, fuses, distribution panels, transformers (if needed for voltage conversion), and wiring rated for the required amperage. Specialized equipment such as motor control centers (MCCs) or variable frequency drives (VFDs) may also be installed to control and optimize power delivery to specific machinery.

Three-Phase Power Considerations

Many industrial machines, particularly motors and heavy equipment, require three-phase power for efficient operation. Electricians must ensure that the electrical system is configured to provide three-phase power where needed. This involves wiring and connecting the phases correctly, balancing loads across phases to prevent overloads, and implementing protective measures such as phase monitoring and voltage regulation.

Safety Measures and Compliance

Safety is paramount in industrial settings, and electricians play a crucial role in ensuring electrical safety measures are in place. This includes proper grounding and bonding of equipment, installation of ground fault circuit interrupters (GFCIs) where required, implementing lockout/tagout procedures for maintenance, and adhering to relevant electrical codes and standards such as NFPA 70E or IEC 60204-1.

Testing and Commissioning

Once the power allocation and equipment installation are complete, thorough testing and commissioning are carried out. This involves testing circuits, verifying voltage levels, checking for proper grounding and insulation, and ensuring that all equipment operates safely and efficiently. Any issues or discrepancies are addressed and corrected before the industrial facility goes into full operation.

Adapting to Changing Needs

Industrial environments are dynamic, with equipment upgrades, expansions, or reconfigurations often occurring over time. Electricians must be prepared to adapt and modify the electrical system as needed to accommodate these changes while maintaining safety, efficiency, and compliance with regulations.

Conclusion

Allocating power for equipment in an industrial property is a complex and crucial task that requires expertise, precision, and a deep understanding of electrical systems and industrial machinery. Electricians play a vital role in ensuring that power distribution meets the demanding needs of industrial operations while prioritizing safety, efficiency, and compliance with industry standards. Their expertise empowers industries to function smoothly, reliably, and with the power needed to drive productivity and innovation.